A post-pandemic world, geopolitical instability and the infinite possibilities made possible by artificial intelligence (AI) have unleashed volatility and significantly altered supply chains. However, Southeast Asia benefits from these changes as an increasing number of manufacturers choose the region as their central hub.1

The seamless flow of goods, information, and finances from raw materials to the end consumer is paramount. This intricate network is orchestrated by supply chain management, a critical function that ensures efficiency, resilience, and customer satisfaction. In this article we examine supply chain management and how to navigate through this challenging terrain.

What is Supply Chain Management?

Definition of Supply Chain Management

Supply chain management refers to the coordination of the production, shipment, and distribution of products, from sourcing raw materials to delivering the final product to customers. The supply chain management process encompasses every activity that helps manage the flow of goods, information, and finances across the value chain.

A well-structured management system ensures seamless collaboration between supply chain partners, allowing companies to anticipate demand, reduce delays, and serve customers better.

Key Components of a Supply Chain Management System

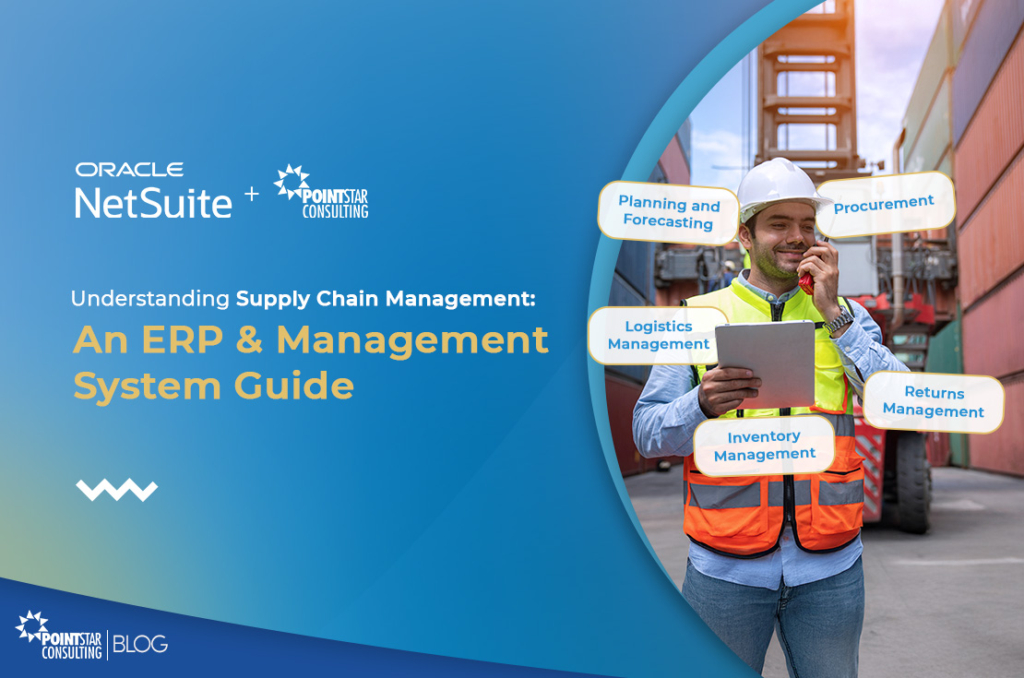

A robust supply chain management system includes the following components:

- Planning and Forecasting: Anticipating demand and aligning resources accordingly.

- Procurement: Sourcing and acquiring materials and components.

- Logistics Management: Coordinating transportation, warehousing, and distribution.

- Inventory Management: Monitoring stock levels to balance supply and demand.

- Returns Management: Handling product returns efficiently and sustainably.

These components form the backbone of supply chain operations, enabling businesses to optimise their supply chain network and ensure a smooth flow of goods.

Importance of Supply Chain Management in Business

Companies risk delays, high operational costs, and poor customer satisfaction without a well-managed SCM system. In contrast, effective SCM drives competitive advantage by increasing agility, reducing costs, and strengthening relationships with supply chain partners.

A solid supply chain strategy aligns with broader business goals and is crucial for industries reliant on fast, accurate deliveries and efficient production cycles.

What are the Benefits of Supply Chain Management?

Enhancing Supply Chain Visibility

Visibility is vital within the supply chain. With real-time data and analytics, businesses can identify bottlenecks, track goods in transit, and proactively respond to disruptions. Enhanced supply chain visibility is crucial in global supply chains, where goods may cross multiple borders.

Improving Inventory Management

Effective inventory management reduces excess stock, minimises stockouts, and frees up capital. By integrating ERP systems with supply chain management software, companies can automate reorder points, forecast demand, and manage stock across locations.

Cost Reduction in Supply Chain Operations

SCM directly impacts the bottom line by minimising transportation costs, reducing waste, and avoiding overproduction. Efficient logistics, streamlined processes, and predictive analytics can yield significant savings across the supply chain.

How Does an ERP System Integrate with Supply Chain Management?

Role of ERP in Managing Supply Chains

An ERP system is the central nervous system for business operations, offering a unified platform for managing finance, procurement, inventory, and logistics. When integrated with SCM, ERP delivers end-to-end visibility and facilitates data-driven decisions across the supply chain.

Benefits of Using SCM Software with ERP

Combining SCM software with an ERP system allows for:

- Real-time data syncing across departments

- Automated workflows for procurement, shipping, and invoicing

- Enhanced collaboration with vendors and distributors

- Better compliance with global trade regulations

These benefits are especially valuable for businesses operating in a global supply environment, where accuracy and coordination are critical.

Examples of Popular Supply Chain Management Software

Some commonly used supply chain management software solutions include:

- Oracle NetSuite SCM

- SAP SCM

- Kinaxis RapidResponse

- Celigo (for integration across multiple platforms)

- Workato (for automating supply chain workflows)

These platforms are designed to support businesses in handling the complexity of supply chain management through automation, analytics, and real-time monitoring.

What are the Types of Supply Chains?

Traditional vs. Modern Supply Chains

Traditional supply chains operate linearly – supplier to manufacturer to distributor to customer. However, modern supply chains are dynamic, digital, and interconnected. They rely on AI, IoT (internet of things), and cloud computing to improve agility and reduce lead times.

Global Supply Chains and Their Challenges

Operating in a global supply chain environment introduces complexities such as geopolitical risks, regulatory compliance, and fluctuating demand. Companies must adopt proactive risk management strategies to maintain continuity and resilience.

Understanding Supply Chain Networks

A supply chain network is the interconnected system of suppliers, manufacturers, warehouses, and retailers. Managing this network efficiently is key to maintaining the flow of goods and meeting customer expectations.

What is the Future of Supply Chain Management?

Emerging Trends in SCM

The future of SCM is data-driven, automated, and customer-centric. Trends reshaping the industry include:

- Predictive analytics for demand forecasting

- AI-powered procurement and planning

- Autonomous vehicles and drones in logistics

- Blockchain for transparency and traceability

Impact of Technology on the Supply Chain Management Process

Technology transforms how companies manage supply chain operations, from automated warehouses to digital twins that simulate supply chain scenarios. These innovations improve both efficiency and agility.

Final Thoughts

Supply chain management is the lifeblood of efficient business operations. With the right management system—supported by ERP and cutting-edge SCM software—companies can navigate global complexities, improve visibility, and meet today’s fast-changing demands. Whether evaluating your current supply chain strategy or planning future improvements, now is the time to invest in smarter, scalable solutions for long-term success.

- Diversifying global supply chains: Opportunities in Southeast Asia. McKinsey & Company. September 5, 2024. https://www.mckinsey.com/industries/logistics/our-insights/diversifying-global-supply-chains-opportunities-in-southeast-asia#/ ↩︎